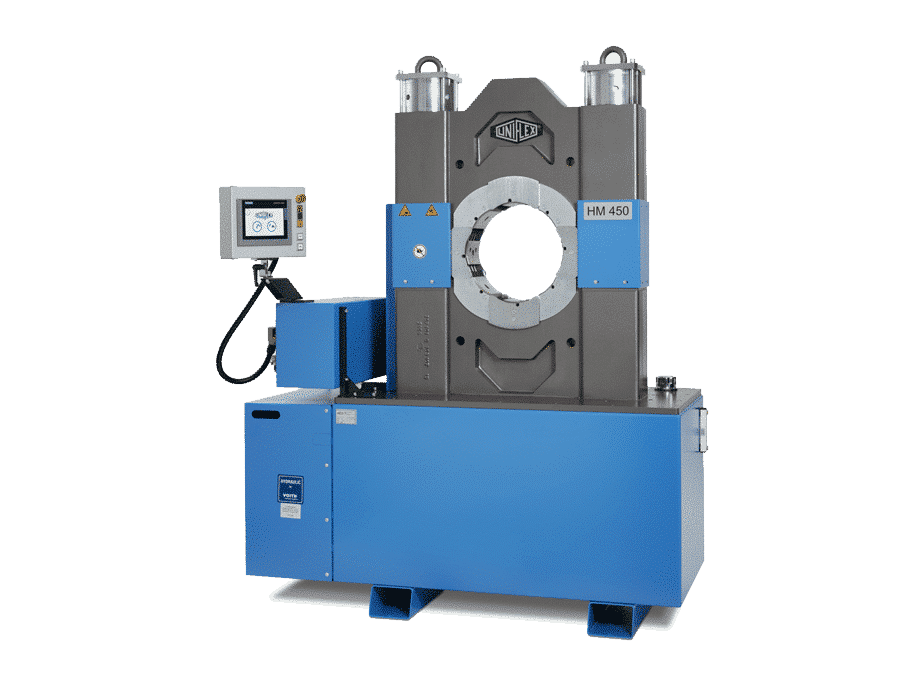

HM 450

Due to the innovative design, which was created especially for special sizes in the industry, as well as the enormous press force of up to 4000 kN, this series sets standards for quality and economy. Added to this are classic features such as user-friendliness and a long service life. The HM 450 thus offers productivity and effectiveness in a compact space.

Features

High-level components and system solutions

- Compact design allows ergonomic working.

- HiLo cylinder – higher performance with reduced heat generation/ without overheating

- Low noise level due to high quality pumps

- Crimping of all valve types due to long base dies

- Reinforced tools optimize product quality

Fixed 6 o’clock jaw

- Safe and force-saving positioning of the workpiece

- Increases productivity and profitability

- Improves occupational safety and reduces operator fatigue

Plain bearing technology

- Lubricant-free – for more cleanliness and longer machine life

- Maximum productivity, with extremely low operating costs

- No contamination of the hose line with grease

- Ideal also for the food and pharmaceutical industry

- Reduces press force loss by up to 20%

- Consistenly accurate crimp force

CE compliant

Technical data

-

-

HM 450

-

Crimp force (kN/Ton)

-

4000 / 400

-

Lubrication eliminated: 20% less friction

-

-

Control

-

Control C.2 + Touch

-

SAE R 15 / 4SH* 1 piece fitting

-

3″

-

SAE R 15 / 4SH* 2 piece fitting

-

3″

-

Max. crimp range (mm)

-

310

-

Opening travel (mm)

-

+ 130

-

Opening without dies (mm)

-

360

-

Base jaw length (mm)

-

150

-

Type of dies

-

245 / 237L / 239-xx

-

Industrial

-

6″ (12″) **

-

90° Elbows

-

3″

-

Closing speed (mm/sec)

-

18

-

Pressing speed (mm/sec)

-

1,4

-

Opening speed (mm/sec)

-

20

-

Noise level (dBA)

-

62

-

Drive (kW)

-

5,5 kW 3 VAC

-

Oil (l)

-

300

-

Length machine (mm)

-

730

-

Width machine (mm)

-

1590

-

Height machine (mm)

-

1915

-

Weight (kg)

-

1900

-

HiDS (Efficient hydraulic

Suction System) -

-

Options

* Special dies (reduced opening).

** Fittings without flanges.

Video

Type of dies

| ø mm | -mm- |

|---|---|

| 54 | 118 |

| 57 | 118 |

| 62 | 118 |

| 67 | 118 |

| 71 | 118 |

| 74 | 118 |

| 78 | 118 |

| 84 | 118 |

| 86 | 118 |

| 90 | 118 |

| 96 | 118 |

| 103 | 118 |

| 106 | 126 |

| 111 | 126 |

| 116 | 126 |

| 121 | 126 |

| 126 | 126 |

| 131 | 126 |

| ø mm | -mm- |

|---|---|

| 6,8 | 50 |

| 9 | 50 |

| 10 | 50 |

| 12 | 65 |

| 14 | 65 |

| 16 | 65 |

| 17 | 65 |

| 19 | 65 |

| 20 | 65 |

| 22 | 65 |

| 24 | 65 |

| 26 | 65 |

| 28 | 80 |

| 30 | 80 |

| 31 | 80 |

| 32 | 80 |

| 34 | 80 |

| 36 | 80 |

| 38 | 80 |

| 39 | 80 |

| 40 | 80 |

| 44 | 80 |

| 47 | 100 |

| 50 | 100 |

| 54 | 100 |

| 57 | 100 |

| 62 | 100 |

| ø mm | -mm- |

|---|---|

| 103 | 130 |

| 106 | 130 |

| 111 | 130 |

| 116 | 130 |

| 121 | 130 |

| 126 | 130 |

| 131 | 130 |

| 136 | 130 |

| 146 | 150 |

| 156 | 150 |

| 170 | 150 |

| 185 | 150 |

| 200 | 150 |

| 230* | 230 |

| 265* | 220 |

| 275* | 220 |

| 305* | 254 |

| *Special dies (reduced opening) |

First Class Advantages

Control C.2 Accessories

Description

Catalogues

20.56 MB | 14. April 2025

12.52 MB | 24. October 2022

11.5 MB | 14. April 2025

1.24 MB | 14. April 2025

4.06 MB | 14. April 2025

3.44 MB | 14. April 2025

1.62 MB | 14. April 2025

868.80 KB | 14. April 2025

2.79 MB | 14. April 2025