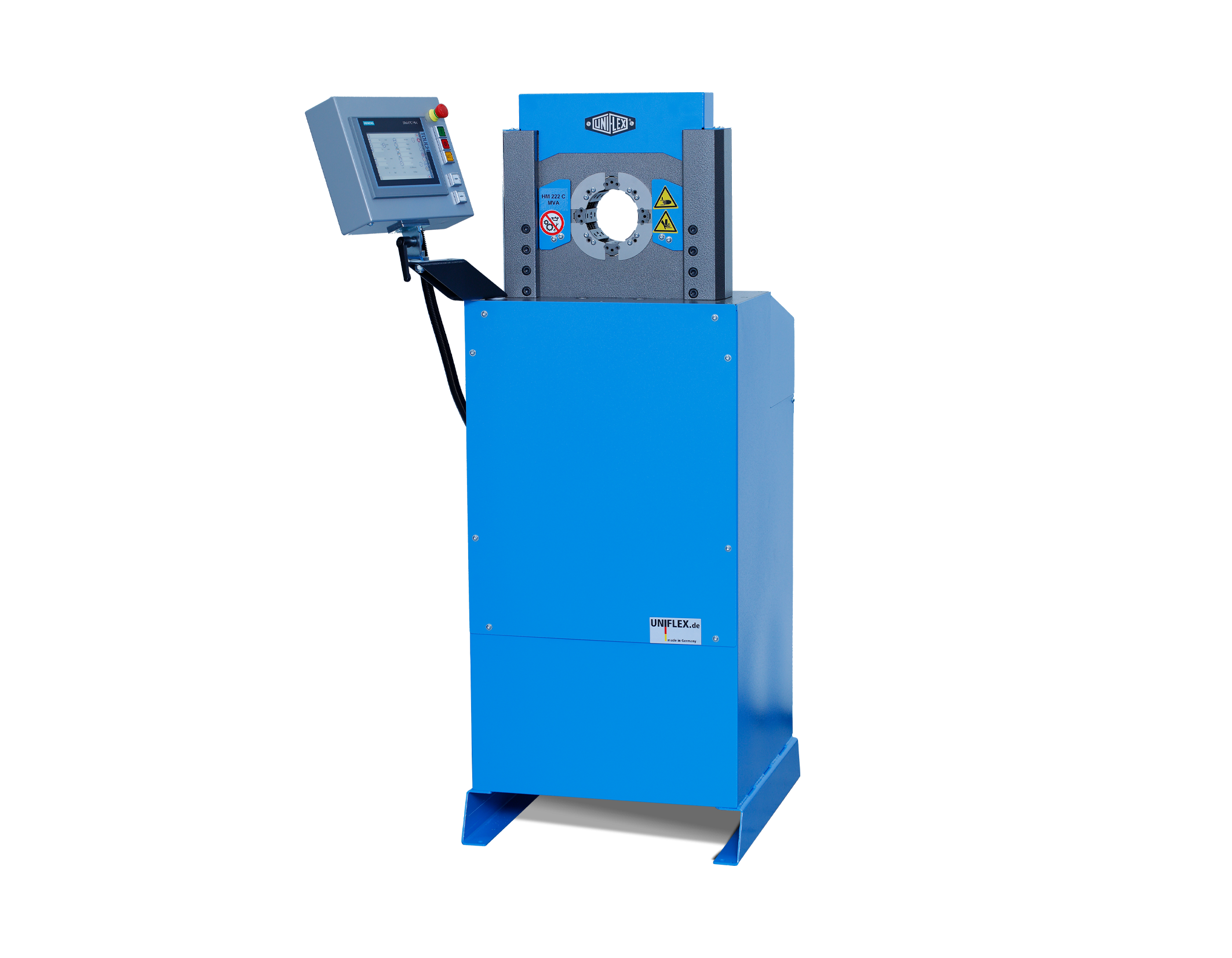

HM 222

Due to their narrow, innovative construction, high level of user friendliness, and long service life, the HM 222 set the standard for quality and cost effectiveness. Their unrivaled accessibility makes ergonomic working possible – optionally from both sides – in production and series manufacturing. The tried and tested greaseless slide bearing technology reduces maintenance costs, and the strong crimping force of up to 1400 /1600 kN is rated for widths up to 1..

Features

High-level components and system solutions

- Compact design allows ergonomic working.

- HiLo cylinder – higher performance with reduced heat generation/ without overheating

- Low noise level due to high quality pumps

Fixed 6 o’clock jaw

- Safe and force-saving positioning of the workpiece

- Increases productivity and profitability

- Improves occupational safety and reduces operator fatigue

Plain bearing technology

- Lubricant-free – for more cleanliness and longer machine life

- Maximum productivity, with extremely low operating costs

- No contamination of the hose line with grease

- Ideal also for the food and pharmaceutical industry

- Reduces press force loss by up to 20%

- Consistenly accurate crimp force

CE compliant

Technical data

-

-

HM 222

-

Crimp force (kN/Ton)

-

1350 / 135

-

Lubrication eliminated: 20% less friction

-

✓

-

Control

-

Control C.2 + Touch

-

SAE R 15 / 4SH* 1 piece fitting

-

1¼ ″

-

4SH* 2 piece fitting

-

1″

-

SAE R 15* 2 piece fitting

-

1″

-

Max. crimp range (mm)

-

70

-

Opening travel (mm)

-

+ 35

-

Opening without dies (mm)

-

105

-

Base jaw length (mm)

-

75

-

Type of dies

-

239

-

Industrial

-

2″

-

90° Elbows

-

1½ “

-

Closing speed (mm/sec)

-

10/20

-

Pressing speed (mm/sec)

-

5/10

-

Opening speed (mm/sec)

-

10/20

-

Noise level (dBA)

-

53

-

Drive (kW)

-

5,5 kW 3 VAC

-

Oil (l)

-

80

-

Length machine (mm)

-

645

-

Width machine (mm)

-

560

-

Height machine (mm)

-

1450

-

Weight (kg)

-

310

* Depending on the fitting.

** Standard: Half power, double speed. (Switchable by control)

*** Outside base jaw lengths: UNIFLEX REQUEST

Video

Type of dies

ø mm |

-mm- |

|---|---|

| 6,8 | 50 |

| 9 | 50 |

| 10 | 50 |

| 12 | 50 |

| 14 | 60 |

| 16 | 60 |

| 17 | 60 |

| 19 | 60 |

| 20 | 60 |

| 22 | 60 |

| 24 | 60 |

| 26 | 75 |

| 28 | 75 |

| 30 | 75 |

| 31 | 75 |

| 32 | 75 |

| 34 | 75 |

| 36 | 75 |

| 38 | 75 |

| 39 | 75 |

| 40 | 75 |

| 44 | 75 |

| 47 | 75 |

| 50 | 75 |

| 54 | 75 |

| 57 | 75 |

| 62 | 75 |

First Class Advantages

Control C.2 Accessories

Description

Catalogues

20.56 MB | 14. April 2025

12.52 MB | 24. October 2022

11.5 MB | 14. April 2025

1.24 MB | 14. April 2025

4.06 MB | 14. April 2025

3.44 MB | 14. April 2025

1.62 MB | 14. April 2025

868.80 KB | 14. April 2025

2.79 MB | 14. April 2025