The manufacture for special applications

At UNIFLEX there are no assembly lines and no large-scale production.

The hose presses and all other equipment and machines are manufactured in the classic manufactory process by hand and in most cases made to order.

Each press is therefore a carefully assembled individual item “Made in Germany” by well-trained specialists.

Elicit customer requirements

Implement requirements

Manufacture special machine

Facts

750 / 75

Pressing force (kN / clay)

70

Pressing range (mm)

Facts

First Class Advantages:

Lubrication-free

Ergonomic

Silent

CE conformity

2 years warranty

FCA

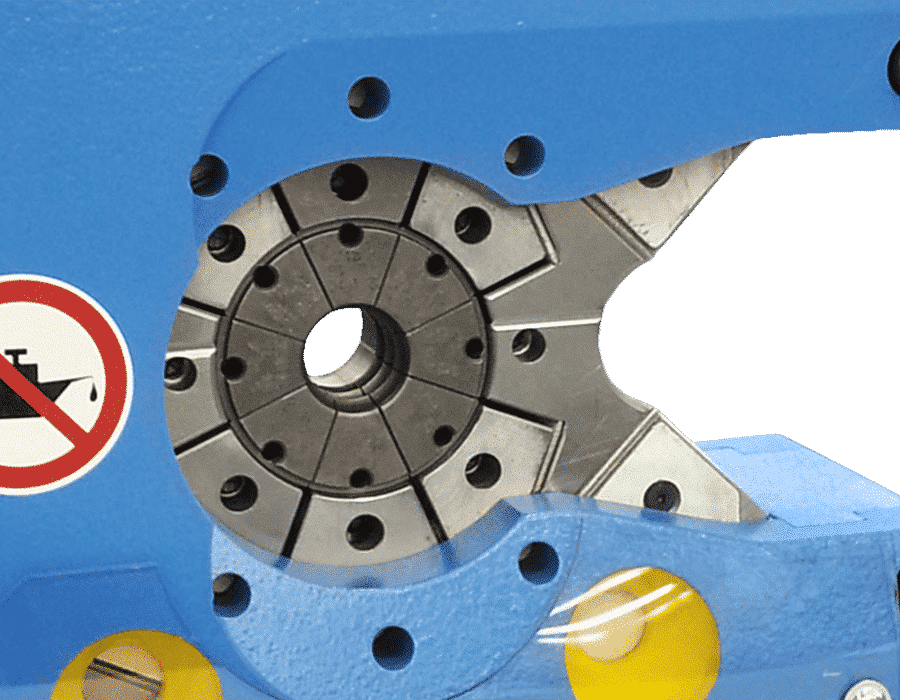

HM 245 Close-up

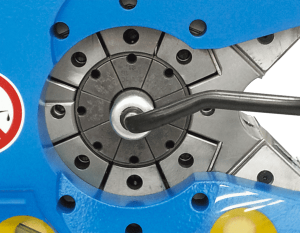

HM 245 Close-up with pipe bending (up to 90°)

Press dies

HM 245 Workspace

Advantages

Innovative design due to C-press tools

- Narrow mold design for easy pressing even of 90° fittings

- Radial feeding of the workpieces

High-level components and system solutions

- High quality pumps – for the reduction of the noise level

Plain bearing technology

- Maximum productivity and low maintenance costs

- Reduces press force loss by up to 20

- Lubricant-free – for more cleanliness and a longer service life of the machine

- No adhesion of dirt particles to the workpiece

Control-C User interface

- Touch control surface

- Programmable progressive press mass and compressive pressures

- Large article storage for production management

- HID-compliant

CE conformity

CE conformity

Advantages

And everything that goes with it

HM 245 Package

A package includes the selected machine incl. accessories.

HM 245 Package = Machine + PB Ø 17, 20, 24, 28, 32, 40, 44, 50

Control C.2

Standard

The following products are supplied with the purchase of the product and are included in the price.

LUF

OPTION: Options are only available ex works – machines cannot be retrofitted with them.

Light on the back of the machine.

Sliding table

OPTION: Options are only available ex works – machines cannot be retrofitted with them.

Features